Introduction

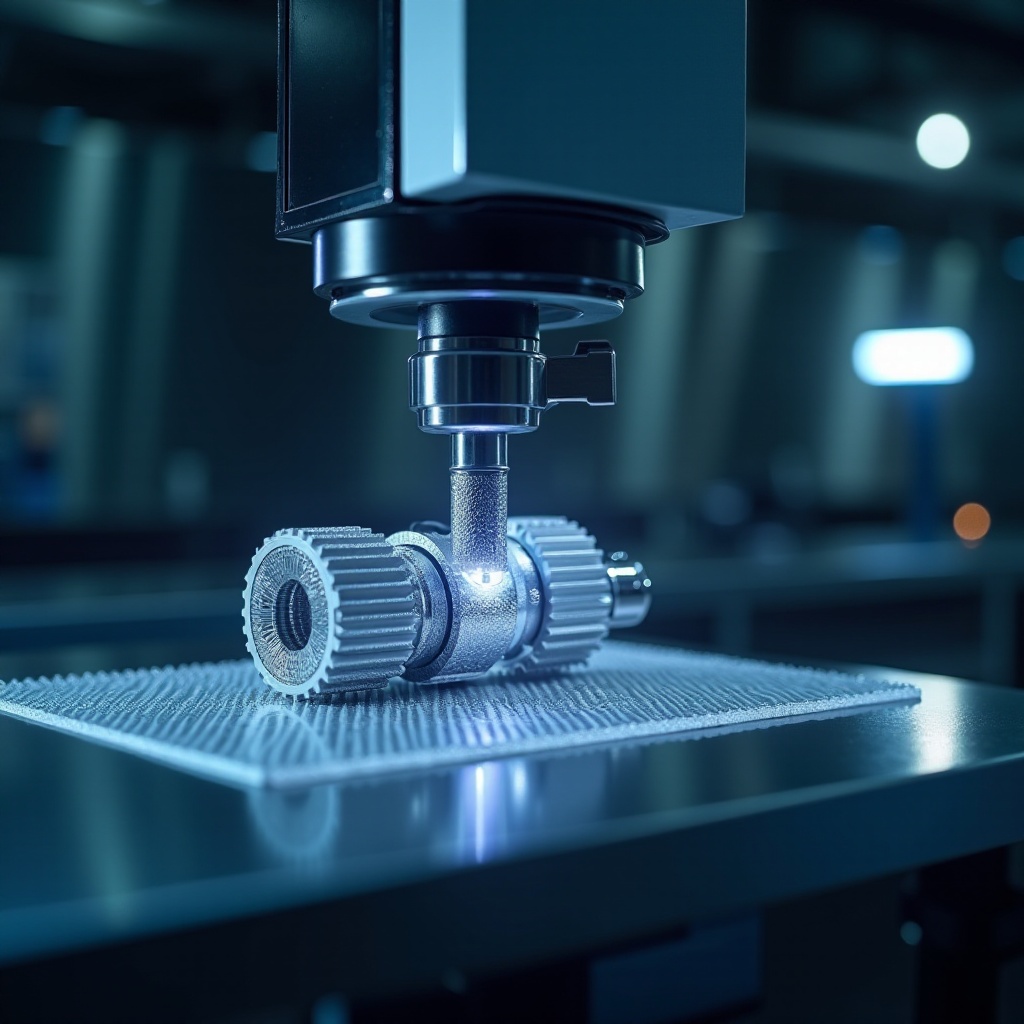

3D scanners have revolutionized the way we approach reverse engineering. Utilizing precise scanning technologies, these devices capture detailed dimensions and geometric data from existing objects. This transformation spans various industries by facilitating the creation, replication, and improvement of products.

What is Reverse Engineering and How 3D Scanners Play a Role?

Reverse engineering involves deconstructing a device or system to reveal its design and functioning principles. It’s widely used for product design, optimization, and competitor analysis. Here, 3D scanners become indispensable tools. They enable the capture of intricate details and geometric data from any physical object, converting this data into a digital model for further enhancements.

3D scanners streamline the reverse engineering process by providing accurate and detailed 3D models that engineers and designers can analyze and modify. Their role is crucial in achieving precision, saving time, and reducing errors during the creation of a replica or an improved version of an existing product.

Top Features to Look for in a 3D Scanner for Reverse Engineering

Choosing the right 3D scanner requires understanding the key features that enhance the reverse engineering process.

Accuracy and Resolution

High accuracy ensures that the 3D scanner captures precise measurements of the object, which is essential for creating reliable digital models. Resolution impacts the level of detail in the scan, so higher resolution is needed for complex and smaller components.

Speed and Efficiency

A scanner that delivers fast results without compromising quality significantly benefits reverse engineering projects, especially in industries where time-to-market is critical. Efficient scanners reduce workflow time and improve productivity.

Software Compatibility

The scanner should be compatible with multiple CAD software solutions to ensure seamless integration into your existing workflow. This flexibility allows you to process, analyze, and modify the scanned data efficiently.

Popular Types of 3D Scanners for Reverse Engineering

Different types of 3D scanners cater to varying needs. Understanding their capabilities helps select the most suitable one for your tasks.

Handheld 3D Scanners

Handheld scanners offer versatility and ease of use. They are ideal for scanning objects in different locations and angles, making them perfect for fieldwork or on-site inspections.

Stationary 3D Scanners

Stationary scanners provide higher stability and often better accuracy. They are suited for scanning larger objects or situations where the scanner remains fixed while the object is rotated or moved.

Desktop 3D Scanners

Desktop scanners are compact and primarily used for smaller objects. They fit well in office or lab environments, providing high precision for intricate parts and small-scale products.

How to Use 3D Scanners for Reverse Engineering Projects: A Step-by-Step Guide

Here’s a detailed guide to effectively using 3D scanners in reverse engineering projects:

Preparing Your Object for Scanning

- Clean the object to remove dust and debris.

- Ensure the object is well-lit to avoid shadows.

- Stabilize the object, especially if it’s lightweight or easily movable.

The Scanning Process

- Position the scanner at the optimal distance from the object.

- Calibrate the scanner per the manufacturer’s instructions.

- Begin the scan, ensuring all surfaces are covered from multiple angles for a complete data set.

Data Processing and Mesh Generation

- Transfer the scanned data to your computer.

- Use the provided software to process the raw data.

- Generate a mesh to create a detailed, accurate 3D model of the scanned object.

Importing Data into CAD Software

- Export the processed mesh data in a compatible format (e.g., STL, OBJ).

- Import the file into your CAD software.

- Use the digital model for further design, analysis, or modification tasks.

Applications of 3D Scanning in Different Industries

The versatility of 3D scanning technology is evident in its wide range of applications across various industries.

Automotive Industry

In the automotive sector, 3D scanners facilitate designing new components, inspecting parts for quality control, and reverse engineering existing car parts for upgrades or custom modifications.

Aerospace Industry

Precision is paramount in aerospace. 3D scanning ensures that components meet stringent safety and performance standards. It’s used in designing, testing, and maintaining aircraft parts.

Manufacturing and Product Design

Manufacturers use 3D scanners to refine product designs, analyze prototypes, and ensure that final products match their design specifications. This technology speeds up the development process and enhances product quality.

Conclusion

3D scanners are an invaluable asset in the reverse engineering toolkit. They offer high precision, efficiency, and integration capabilities essential for diverse industries. By understanding their uses, types, and key features, businesses can leverage 3D scanning technology to innovate and optimize their manufacturing processes.

Frequently Asked Questions

What is the best 3D scanner for reverse engineering?

The best 3D scanner depends on your specific needs, including desired accuracy, object size, and budget. Leading brands offer robust options that cater to various requirements.

How accurate are 3D scanners for reverse engineering?

Most high-quality 3D scanners provide accuracy within microns, making them highly reliable for detailed reverse engineering tasks and precision-intensive industries.

Can 3D scanners work with any CAD software?

Many 3D scanners come with software that allows easy export to popular CAD formats. However, compatibility should be checked to ensure smooth workflow integration.